The food and beverage manufacturing industry is essential for producing a wide range of products, from packaged goods to beverages, catering to global consumer demands. This sector faces unique challenges, including maintaining food safety, ensuring product quality, and navigating complex regulatory requirements. As consumer preferences evolve and demand for healthier, more sustainable options rises, the industry must innovate while keeping efficiency and compliance at the forefront. Technology-driven solutions in Environmental, Health, and Safety (EHS) are critical for streamlining operations, ensuring regulatory compliance, and promoting worker safety in this high-demand sector.

Food Safety and Quality Assurance: With increasing scrutiny over foodborne illnesses, maintaining food safety and quality is a top priority. EHS solutions help companies meet stringent regulations and track production processes to ensure product safety.

Health and Nutrition Trends: There’s an increasing demand for healthier, organic, and clean-label products, requiring manufacturers to adapt their production lines to meet changing consumer preferences.

Worker Safety and Operational Efficiency: The manufacturing environment is often fast-paced and labor-intensive, making worker safety a key concern. Implementing proactive safety measures and improving operational efficiency can help reduce injuries and optimize production processes.

Technology Integration: Automation and AI are playing an increasingly important role in improving efficiency and product traceability. EHS technology that integrates real-time data analytics is helping food and beverage companies maintain compliance, enhance safety, and optimize supply chain management.

The food and beverage manufacturing industry is governed by a wide range of regulations to ensure food safety, quality, and environmental responsibility. Key standards include:

Food Safety Modernization Act (FSMA): Enforced by the FDA, FSMA shifts the focus of food safety from response to prevention. It requires companies to establish preventive controls to ensure food safety across the supply chain.

FDA Regulations (USA): The Food and Drug Administration (FDA) oversees food labeling, safety, and manufacturing practices in the U.S. Compliance with FDA guidelines is crucial for ensuring product safety and consumer health.

Hazard Analysis and Critical Control Points (HACCP): An internationally recognized food safety management system, HACCP focuses on identifying and controlling food safety hazards. It is required in many countries and is essential for compliance in food manufacturing.

ISO 22000: This international standard outlines requirements for food safety systems, focusing on controlling food safety hazards and ensuring compliance with regulatory requirements across the entire food supply chain.

Global Food Safety Initiative (GFSI): GFSI standards, such as SQF (Safe Quality Food) and BRC (British Retail Consortium), help food manufacturers implement food safety and quality systems recognized internationally.

Occupational Safety and Health Administration (OSHA): OSHA’s workplace safety regulations ensure that food manufacturing facilities provide a safe working environment, protecting workers from injuries, exposure to hazardous materials, and unsafe working conditions.

Packaging and Labeling Regulations: In addition to food safety regulations, manufacturers must comply with labeling requirements that include nutritional information, ingredient disclosures, and allergen warnings, ensuring transparency and consumer safety.

European Union Food Law (EC 178/2002): This law provides the foundation for food safety legislation in the EU, establishing principles for food safety, traceability, and recall procedures to protect public health.

Compliance with these standards is critical for maintaining product safety, avoiding legal penalties, and ensuring consumer trust. Adhering to food safety regulations helps prevent costly recalls, enhances brand reputation, and fosters a culture of safety and quality. In a highly regulated industry, meeting these requirements with the help of robust EHS technology solutions is essential to staying competitive and protecting both consumers and workers.

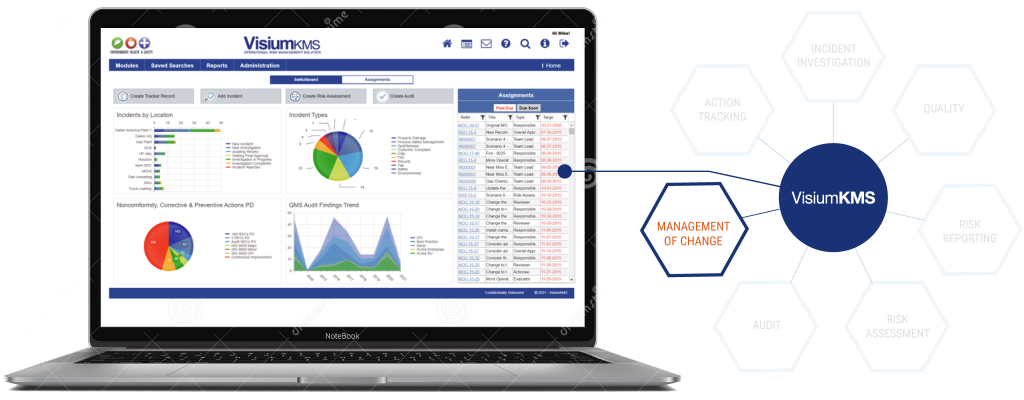

VisiumKMS offers tailored solutions to streamline EHS operations, reduce risks, and help oil and gas companies thrive in a challenging, regulated environment. Here is how each module can support your business.

Use Case: The Change Management Tracker module allows the company to manage and track changes across all processes, from ingredient sourcing to production lines. It ensures that all changes are documented, assessed for potential risks, and properly communicated to the relevant teams. This helps prevent errors, maintain food safety standards, and ensure that product modifications comply with FSMA and HACCP regulations.

Use Case: The Risk Assessment module helps the company conduct thorough risk assessments for new equipment and processes. It allows for the identification, evaluation, and mitigation of potential risks related to food safety, employee safety, and environmental impact. By using real-time data and AI-driven insights, VisiumKMS helps ensure that potential risks are identified and managed before they affect operations, ensuring compliance with HACCP and OSHA safety standards.

Use Case: The Incident Investigation module enables the company to record, track, and investigate the contamination event in real-time. The platform helps identify the root cause, whether it’s related to equipment failure, human error, or supply chain issues. It also generates corrective and preventive actions (CAPA) to prevent recurrence. The module helps streamline compliance with FDA and ISO 22000 standards by ensuring thorough documentation and actionable insights.

Use Case: The Quality and CAPA module allows the company to track and manage quality issues in real-time, identifying the root cause of the problem. VisiumKMS then generates CAPA reports and assigns tasks to the relevant teams to address the issue and prevent it from recurring. With integrated reporting features, the platform ensures that the company remains compliant with HACCP and ISO 22000, and provides traceability for audits and inspections.

Use Case: The Audit and Compliance module streamlines the preparation for audits by providing easy access to historical data, compliance records, and safety reports. VisiumKMS automates compliance checks and provides real-time updates, ensuring that all necessary documentation is available for auditors. The system reduces audit preparation time and helps ensure the company is consistently compliant with FDA, EU regulations, and ISO 22000 standards.

Use Case: The Observations module allows employees to report observations on safety, hygiene, and environmental concerns directly from the production floor. The platform automatically tracks, categorizes, and prioritizes observations, ensuring that all potential issues are addressed quickly. The system generates follow-up actions, making sure corrective measures are implemented and tracked, ensuring compliance with OSHA and EPA regulations for worker safety and environmental impact.

VisiumKMS uses advanced AI agents to help your business stay agile in an ever-evolving regulatory landscape. Our AI-driven platform continuously adapts to changing business rules and regulations, ensuring compliance in real-time. By analyzing vast amounts of data, VisiumKMS AI agents help you transform raw information into actionable insights, empowering your team to make informed decisions. This proactive approach helps streamline operations, reduce risk, and enhance overall efficiency, keeping your business ahead of the curve.

Implementing VisiumKMS in the food and beverage manufacturing sector can lead to substantial financial gains by enhancing operational efficiency, ensuring compliance, and improving safety performance. Below are key areas where VisiumKMS can help organizations achieve a strong ROI:

1. Cost Savings through Operational Efficiency

Streamlined Processes: By automating EHS management, VisiumKMS reduces manual data entry, paperwork, and administrative tasks. This results in significant time savings and operational efficiency.

2. Compliance and Risk

Reduced Compliance Costs: Implementing EHS software like VisiumKMS can lead to a 14% increase in productivity by automating reporting, auditing, and training processes.

3. Enhanced Safety Performance

Incident Reduction: Effective incident reporting and investigation tools in VisiumKMS help identify and mitigate risks, reducing workplace incidents and associated costs.

Example 01:

A global food manufacturer implemented VisiumKMS to streamline their supplier change management process. The digital solution facilitated efficient collaboration among suppliers, leading to significant operational improvements. Source: VKMS

Example 02:

Implementing an EHS allows for compliance streamlining that reduces the risk of non-compliance penalties.

Source: TENFORCE

Example 03:

Implementing EHS software experienced a decrease in workplace accidents, leading to reduced workers’ compensation claims and insurance premiums. Source: SafetyStratus

ROI Benchmark

In the food processing industry, experts note that an ROI of over 5% is considered favorable due to the capital-intensive nature of operations. By leveraging VisiumKMS to streamline processes, enhance compliance, and improve safety, companies can achieve substantial financial returns while maintaining operational excellence.

VisiumKMS simplifies compliance with complex food safety regulations such as FSMA, HACCP, ISO 22000, and FDA requirements. Our platform automates tracking, reporting, and documentation, reducing the risk of non-compliance penalties and ensuring that your operations consistently meet regulatory standards across multiple regions.

VisiumKMS offers real-time incident tracking and investigation tools, enabling food and beverage manufacturers to quickly identify and address potential safety risks. By reducing workplace accidents, product defects, and food safety violations, VisiumKMS improves operational efficiency, lowers insurance costs, and ensures a safer work environment for employees.

By integrating real-time quality control measures and continuous monitoring, VisiumKMS helps manufacturers ensure consistent product quality, minimize defects, and prevent costly recalls. The platform improves operational efficiency by streamlining workflows, reducing manual data entry, and providing actionable insights that drive data-driven decision-making for optimal production outcomes.

We collaborate with industry-leading companies and organizations that enhance our solutions, validate our capabilities, and ensure the highest standards in EHS management.