The manufacturing industry plays a critical role in driving global economies by producing a wide range of products, from machinery to consumer goods. This sector faces numerous challenges, including ensuring operational efficiency, managing safety risks, and navigating complex regulatory landscapes. As global competition intensifies and consumer demands evolve, manufacturers must embrace innovation while optimizing productivity, reducing costs, and ensuring regulatory compliance. Technology-driven solutions in Environmental, Health, and Safety (EHS) are essential for streamlining operations, enhancing worker safety, and maintaining regulatory standards in this highly competitive sector.

Digital Transformation and Automation

Manufacturers are adopting AI, IoT, and automation to improve productivity, reduce errors, and optimize operations.

Worker Safety and Risk Management

Proactive safety measures and real-time risk assessments are key to reducing workplace accidents and ensuring compliance.

Sustainability and Waste Reduction

Manufacturers are focusing on reducing waste, improving energy efficiency, and meeting stricter environmental regulations.

Supply Chain Resilience and Transparency

There’s a growing emphasis on enhancing supply chain transparency, improving traceability, and ensuring product quality.

Regulatory Compliance and Data Management

Manufacturers are leveraging EHS software to streamline compliance, automate reporting, and manage regulatory changes more efficiently.

The manufacturing industry is governed by numerous regulations and standards designed to ensure product quality, worker safety, environmental protection, and regulatory compliance. Adhering to these standards is essential to mitigate risks, avoid penalties, and maintain operational efficiency:

Adhering to industry standards and regulations helps manufacturers reduce operational risks, avoid legal liabilities, and enhance product quality. Compliance also builds consumer trust, supports sustainability efforts, and ensures that the company remains competitive in a highly regulated and global market.

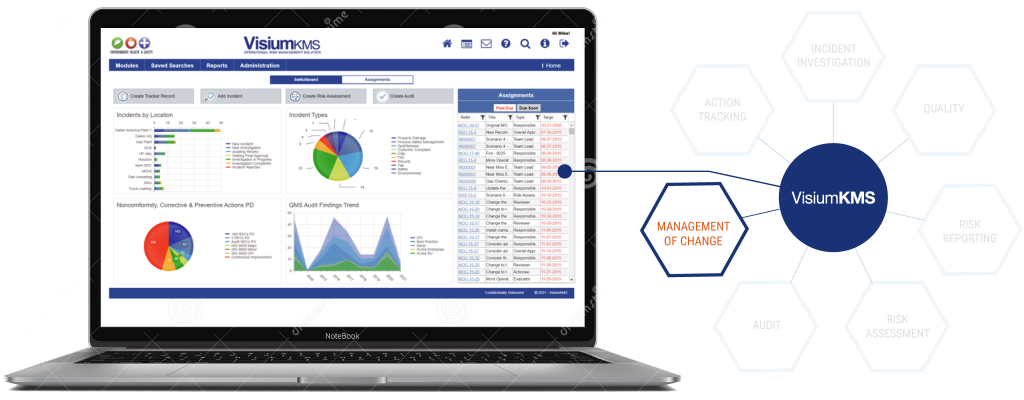

VisiumKMS offers tailored solutions to streamline EHS operations, reduce risks, and help oil and gas companies thrive in a challenging, regulated environment. Here is how each module can support your business.

Use Case: The Change Management Tracker module records and tracks changes made to equipment, processes, and materials. It ensures that any changes are evaluated for potential risks, documented, and communicated to all stakeholders. This helps prevent disruptions in production and ensures compliance with safety and regulatory standards, streamlining the change process.

Use Case: The Risk Assessment module allows the company to systematically evaluate potential risks associated with new product lines and machinery. VisiumKMS generates risk mitigation plans, helping to reduce hazards in the production process and ensuring compliance with safety standards. This proactive approach helps prevent costly safety incidents and minimizes operational downtime.

Use Case: The Incident Investigations module helps the company track, document, and investigate the spill. It enables real-time incident reporting, root cause analysis, and the implementation of corrective actions. By providing a structured approach to incident investigations, VisiumKMS helps prevent recurrence, improves safety performance, and reduces liability risks.

Use Case: The Quality and CAPA module helps the manufacturer document the quality issue, perform a root cause analysis, and initiate corrective and preventive actions. VisiumKMS tracks these actions through to completion, ensuring that the issue is resolved and preventing future defects. This process improves product quality and enhances customer satisfaction, while ensuring compliance with ISO 9001 and other relevant standards.

Use Case: The Audit and Compliance module centralizes all compliance documentation, audit records, and regulatory reports. VisiumKMS streamlines the audit process by providing real-time access to all required data, making the audit preparation and execution more efficient. It helps ensure the company meets regulatory requirements and avoids penalties, while also identifying opportunities for continuous improvement.

Use Case: The Observations module allows employees to quickly and easily report safety concerns or quality issues from the production floor. The system captures the observation, prioritizes it for resolution, and automatically notifies the relevant stakeholders. This ensures that issues are addressed promptly, improving workplace safety and reducing the likelihood of accidents or downtime.

VisiumKMS uses advanced AI agents to help your business stay agile in an ever-evolving regulatory landscape. Our AI-driven platform continuously adapts to changing business rules and regulations, ensuring compliance in real-time. By analyzing vast amounts of data, VisiumKMS AI agents help you transform raw information into actionable insights, empowering your team to make informed decisions. This proactive approach helps streamline operations, reduce risk, and enhance overall efficiency, keeping your business ahead of the curve.

Implementing VisiumKMS in the Manufacturing sector can yield significant financial benefits by enhancing operational efficiency, reducing compliance risks, and improving safety performance. Here are some key areas where VisiumKMS can help organizations achieve a strong ROI:

1. Increased Efficiency and Cost Savings

Implementing VisiumKMS helps manufacturers streamline their operations by automating EHS processes, which leads to significant cost savings. This reduces manual work, minimize human error, and optimize resource management.

2. Compliance and Risk

Reduced Compliance Costs: Implementing EHS software like VisiumKMS can lead to a 14% increase in productivity by automating reporting, auditing, and training processes.

3. Enhanced Safety Performance

Incident Reduction: Effective incident reporting and investigation tools in VisiumKMS help identify and mitigate risks, reducing workplace incidents and associated costs.

Example 01:

A manufacturing company replaced manual reporting with VisiumKMS, achieving a 30% reduction in administrative time spent on compliance management.

Source: NAEM.ORG

Example 02:

By maintaining compliance with OSHA standards, a manufacturing firm avoided costly regulatory violations and improved its safety record. Source: TENFORCE

Example 03:

Implementing EHS software experienced a decrease in workplace accidents, leading to reduced Health & Safety costs by 21 – 39%. Source: CBIZ

ROI Benchmark

In the manufacturing industry, experts note that an ROI of over 5% is considered favorable due to the capital-intensive nature of operations. By leveraging VisiumKMS to streamline processes, enhance compliance, and improve safety, companies can achieve substantial financial returns while maintaining operational excellence.

VisiumKMS automates compliance with key industry regulations like OSHA and ISO 9001, helping manufacturers avoid penalties and stay on top of changing requirements. The platform also proactively identifies and mitigates risks, ensuring smoother operations and reducing the likelihood of disruptions due to non-compliance or safety incidents.

By leveraging real-time data and automation, VisiumKMS improves production efficiency. The platform tracks critical metrics such as worker safety, product quality, and environmental impact, offering actionable insights that enable manufacturers to make informed decisions, reduce downtime, and optimize resource allocation, resulting in cost savings and increased productivity.

VisiumKMS promotes a safety-first culture by providing tools for real-time incident reporting, risk assessment, and corrective actions. This proactive approach reduces workplace accidents, enhances employee well-being, and lowers insurance premiums, while helping manufacturers meet the highest safety standards and regulations.

We collaborate with industry-leading companies and organizations that enhance our solutions, validate our capabilities, and ensure the highest standards in EHS management.