The oil and gas industry is a global leader in energy production, involving complex operations such as exploration, extraction, refining, and distribution. This sector faces significant environmental and safety challenges, from the potential for hazardous spills to managing emissions and ensuring worker safety in high-risk environments.

Effective EHS (Environmental, Health, and Safety) management is crucial in minimizing risks and ensuring sustainable practices. With growing pressure from regulators and the public, compliance with environmental regulations and occupational safety standards is essential.

Technological innovations and regulatory changes further complicate EHS efforts, requiring advanced solutions to ensure ongoing compliance. Furthermore, sustainability and carbon reduction have become central to long-term industry viability. Given these challenges, adopting a comprehensive EHS management system is not just a regulatory requirement but a competitive advantage.

The oil and gas industry is governed by stringent regulations to ensure environmental protection, worker safety, and operational accountability. Below are key regulations that significantly impact the sector:

Compliance with these standards is essential for minimizing operational risks, avoiding legal penalties, and maintaining a company’s reputation. Meeting these requirements also supports sustainability goals and improves overall efficiency, positioning companies for long-term success in a rapidly changing global energy landscape.

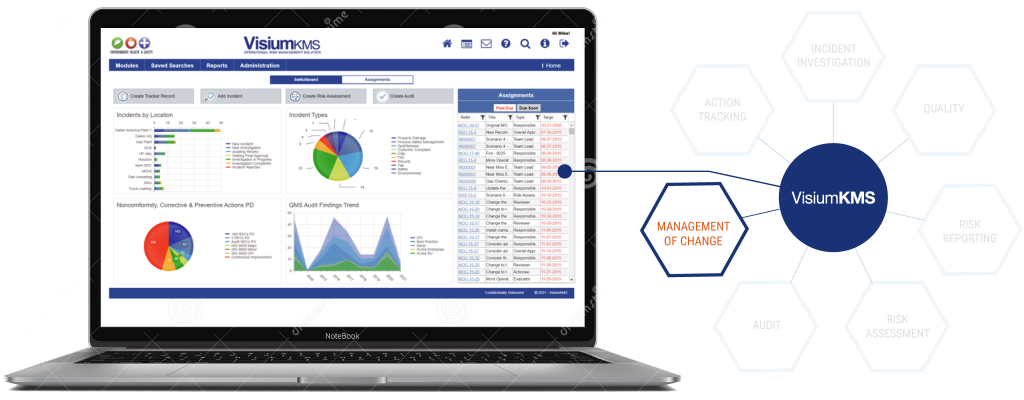

VisiumKMS offers tailored solutions to streamline EHS operations, reduce risks, and help oil and gas companies thrive in a challenging, regulated environment. Here is how each module can support your business.

Use Case: Implement the Tracker module to meticulously monitor the status of safety equipment inspections across all your sites, ensuring compliance with OSHA regulations. Quickly identify and address overdue inspections, preventing potential hazards and maintaining a safe working environment. Streamline your inspection process, saving valuable time and resources while mitigating compliance risks.

Use Case: Employ the Risk module to conduct comprehensive risk assessments of your operations, identifying potential hazards and evaluating the effectiveness of existing safety controls. Prioritize risk mitigation efforts based on the severity and likelihood of each risk, ensuring resources are focused on the most critical areas. Develop and implement robust risk management strategies to minimize incidents and maintain regulatory compliance.

Use Case: Use the Incidents module to streamline incident reporting and investigation processes, ensuring timely and accurate documentation of all safety events. Conduct in-depth root cause analyses, identifying underlying factors contributing to incidents and preventing future occurrences. Stay compliant with regulatory reporting requirements while promoting a culture of continuous safety improvement.

Use Case: Integrate the Quality and CAPA module to manage deviations, non-conformances, and corrective actions related to safety and operational processes, ensuring adherence to industry standards. Streamline the CAPA process, enabling rapid identification of root causes, implementation of effective corrective actions, and verification of solution efficacy. Reduce operational disruptions and maintain quality by preventing reoccurrence of safety incidents and process failures.

Use Case: Leverage the Audit module to conduct thorough safety audits, assessing adherence to EPA and OSHA’s Process Safety Management (PSM) standards for critical equipment and processes. Generate comprehensive audit reports that pinpoint areas for improvement and corrective actions, thereby reducing risk of regulatory violations. Proactively improve your safety programs and ensure your operations consistently meet industry best practices.

Use Case: Empower employees to easily report safety observations and near misses using the Observations module, fostering a proactive safety culture across your operations. Track the status of each observation, ensuring prompt resolution of potential hazards and preventing incidents from escalating. Improve safety performance and reduce risk by addressing concerns before they become critical safety issues.

VisiumKMS uses advanced AI agents to help your business stay agile in an ever-evolving regulatory landscape. Our AI-driven platform continuously adapts to changing business rules and regulations, ensuring compliance in real-time. By analyzing vast amounts of data, VisiumKMS AI agents help you transform raw information into actionable insights, empowering your team to make informed decisions. This proactive approach helps streamline operations, reduce risk, and enhance overall efficiency, keeping your business ahead of the curve.

Implementing VisiumKMS in the Oil & Gas sector can yield significant financial benefits by enhancing operational efficiency, reducing compliance risks, and improving safety performance. Here are some key areas where VisiumKMS can help organizations achieve a strong ROI:

1. Cost Savings through Process Efficiency

Streamlined Operations: By automating and integrating EHS processes, VisiumKMS helps reduce manual errors and administrative burdens, leading to cost savings.

2. Compliance and Risk

Reduced Compliance Costs: VisiumKMS ensures adherence to OSHA and EPA regulations, minimizing the risk of fines and penalties associated with non-compliance.

3. Enhanced Safety Performance

Incident Reduction: Effective incident reporting and investigation tools in VisiumKMS help identify and mitigate risks, reducing workplace incidents and associated costs.

Example 01:

A large Oil & Gas company replaced a redundant legacy system with VisiumKMS, achieving a multi-language configured solution that improved operational efficiency and reduced costs.

Example 02:

By maintaining compliance with Process Safety Management (PSM) standards, companies can avoid costly regulatory violations and improve their safety record.

Example 03:

Improved safety performance leads to lower workers’ compensation claims and reduced downtime, contributing to increased productivity and profitability.

ROI Benchmark

In the Oil & Gas industry, an ROI of over 15% is generally considered favorable due to the capital-intensive nature of operations. By leveraging VisiumKMS to streamline processes, enhance compliance, and improve safety, companies can achieve substantial financial returns while maintaining operational excellence.

We collaborate with industry-leading companies and organizations that enhance our solutions, validate our capabilities, and ensure the highest standards in EHS management.